LEGO 3D PRINT FILES UPDATE

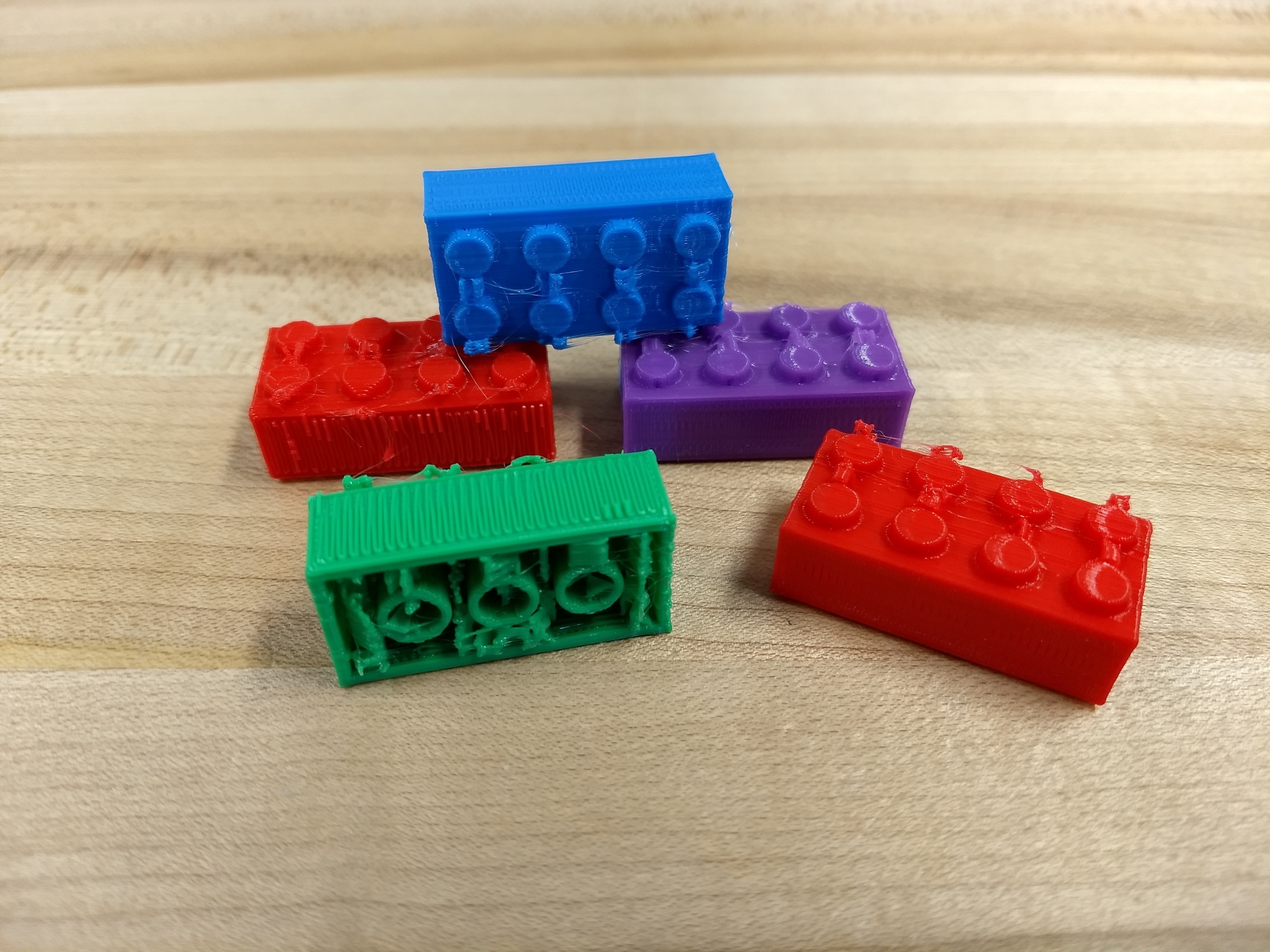

It is as simple as fitting two blocks together and editing a text file, material.scad to indicate which test block fits best.īefore you print the calibration beam, be sure to set the flexible_material and large_nozzle settings in material.scad.Īfter you print the clibration beam, you update three settings to get a tight fit: top_tweak, bottom_tweak and axle_hole_tweak. Calibration is a one time process for each material. To correct for this, we adjust the models slightly for your printing process. Your printer, slicer settings, and plastic effect the precise fit. PELA Calibration Beam, Normal Filament PELA Calibration Beam for standard filament (non-flexible). You can also configure slicing and printing directly from OpenSCAD. Also for large models and a fast machine, Edit | Preferences | Advanced | Turn off rendering at _1000000_ and disable OpenGL 1.0 compatability. After install, Edit | Preferences | Features | Customizer | Enable.

LEGO 3D PRINT FILES SOFTWARE

The software needed is also free and open source, OpenSCAD. Then update your settings in material.scad then one time calibration is complete. Test fit the top, bottom and sides to get something which is tight but not too tight. Most users will want the one linked below unless they are printing with flexible filament. There are several possible calibration beams. Now open any model in OpenSCAD, press F6 to generate the model then F7 to export an STL. Update the best top_tweak and bottom_tweak into material.scad. TL DR : To get a nice snap fit for your printer, slicer settings and material, print a calibration beam and test fit commercial bricks to the top knobs, bottom sockets and side technic holes. See the Slicer Recommendations for information about different printing materials we have tested. See Advanced Setup for additional tricks.

LEGO 3D PRINT FILES DOWNLOAD

Example enclosures with many options for custom sensors, actuators, computers and IoT devices are included, or create your own.

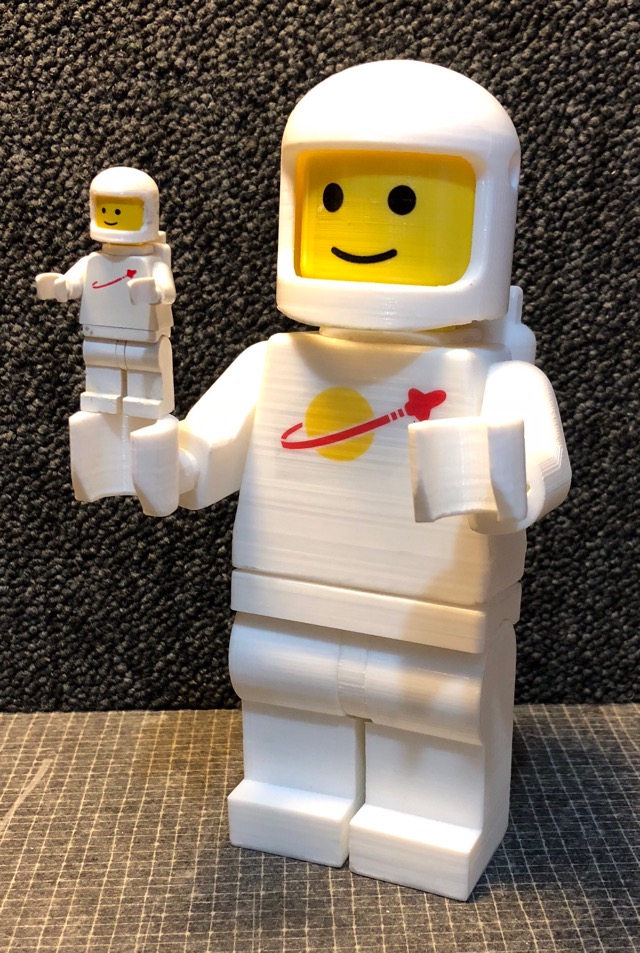

One time calibration gives perfect snap-together objects in exotic materials and geometries to help you explore your ideas and build with exotic materials and any motors and electronics you like. PELA blocks are designed for easy 3D printing, strength, and rapid customization using free software. Now you can design models without coding and snap them together! LEGO-compatible Parametric 3D Printed Blocks This model is saved as a drop down preset of the PELA Technic Mount model. Now we can rapidly iterate our models in the field. Moving sliders in the customizer graphical interface of the PELA Technic Mount created this functional prototype enclosure with nicely calibrated snap fit connectors. We measured the length, width and thickness of this board. The fastest way to get support on designing and 3D printing your custom part is on Discord PELA Blocks PELA Blocks

0 kommentar(er)

0 kommentar(er)